Mastering Engineering Change Management: My Journey from Chaos to Control

From my years of building We Level Up rehab centers into a successful 9-figure business, engineering change management helped us succeed. I’ve learned that change isn’t just inevitable—it’s the lifeblood of growth. Here’s what I learned: Good engineering change management is important. Even small changes can disrupt your entire operation.

Let me share something personal. Early in my entrepreneurial journey, we had “simple” service model updates that seemed straightforward. What followed was months of chaos, confused teams, and frustrated customers. That tough experience taught me that engineering change management is not just a process. It is the key to lasting business growth. I built our change management process incorporating tools such as the Personal Growth Plan Template, and Leadership Growth Strategies to gain next-level performance metrics.

Today, I want to share the engineering change management strategies that changed our business model. Proper change and management strategies helped many entrepreneurs I’ve coached create strong and flexible organizations. No matter if you are managing product development, manufacturing, or service delivery, these insights can help you. They will transform a significant challenge into a competitive advantage.

Jump To

Table of Contents

Best Practices for Optimizing Engineering Change Management

Engineering Change Management (ECM) is the backbone of innovation and operational efficiency in both product and service organizations. When done right, it ensures that every design change, process improvement, or service upgrade goes smoothly. It also helps keep costs low. It also avoids disruptions for customers and internal operations.

In this Engineering Change Management guide, we will look at the strategies, tactics, and plans needed to improve your ECM process. Gain practical engineering change managementtips for teams. Streamline the requests for engineering change management. Focus on the engineering change management workflows and their impact assessments. Find best practices for getting and documenting your progress through engineering change management approvals. Develop into engineering change management , monitoring, and execution. Engineering change management best practices can reduce errors, lower risks, and speed up change adoption in the organization.

You can use these engineering change management insights to improve your work. They will help you make ECM a key part of innovation and business growth.

Continue on for the full engineering change management Process, Tactics & Planning forms, and overview section. I’ll break down each engineering change management (ECM) step by step for both products and services.

What is Engineering Change Management?

Engineering change management is a systematic approach to controlling modifications in your product’s design, manufacturing process, or documentation throughout its lifecycle. Think of it as your business’s immune system—protecting against costly errors while enabling necessary evolution.

As someone who helped guide over 600 team members through countless transformations, I can tell you that change and management go hand in hand. You can’t have sustainable growth without both elements working in harmony.

The definition of change management is straightforward. It connects your business’s current state to its future goals. This link is created with careful planning and carried out with care.

Why Engineering Change Management is Critical for Your Success

I’ve worked with many entrepreneurs. I’ve seen a common pattern. Businesses that adapt to change succeed. Those who struggle with change face challenges

- Costly Rework: Uncontrolled changes can increase project costs. Research from the Air Force Institute of Technology shows that costs can rise by up to 72%

- Team Confusion: When everyone isn’t aligned on changes, productivity plummets

- Customer Dissatisfaction: Inconsistent products or services damage your reputation

- Regulatory Issues: In regulated industries, poor change management can lead to compliance violations

- Missed Opportunities: Slow change processes mean competitors beat you to market.

I recall a client who was losing money each month due to ineffective engineering change management. In six months of using good change management models, they not only stopped those losses but also raised their profit margin.

Here are some of the tools, along with engineering change management , we used to gain a competitive advantage:

- Applying my Business Coach Success Blueprint.

- Utilizing Self-Improver Habits & Strategies.

- Create a growth and transformation plan.

The Core Engineering Change Management Process

Based on my experience transforming organizations, here’s the proven framework that works:

1. Change Request Initiation

Every change begins with a formal request. Whether it comes from engineering, production, quality assurance, or customer feedback, document it in an Engineering Change Request (ECR). This isn’t bureaucracy—it’s protection.

Key elements of every ECR:

- Clear description of the proposed change

- Business justification and expected benefits

- Potential risks and impact assessment

- Timeline requirements

- Resource needs

Engineering change management request form for a product

Engineering change management request form for products

Here’s a simplified Engineering Change Management Request Form. You will fill out an engineering change management Impact Analysis, Approval Workflow, and Implementation Plan as separate forms later.

Engineering Change Management (ECM) Request Form

Form ID: ___________________________

Date Submitted: ____________________

Requested By: ______________________

Department: ________________________

Contact Email/Phone: ________________

1. Change Request Summary

| Field | Description |

|---|---|

| Product/Part Name | _________________________________________ |

| Product/Part Number | _________________________________________ |

| Current Revision/Version | _________________________________________ |

| Proposed New Revision/Version | _________________________________________ |

| Change Type | ☐ Design ☐ Material ☐ Process ☐ Documentation ☐ Software ☐ Other: ___________ |

| Urgency Level | ☐ Routine ☐ High Priority ☐ Immediate/Stop-Ship |

2. Reason for Change

- ☐ Product improvement

- ☐ Cost reduction

- ☐ Supplier change

- ☐ Regulatory/compliance requirement

- ☐ Customer request

- ☐ Correct defect/issue

- ☐ Other: __________________________

Detailed Description of Issue or Opportunity:

3. Description of Proposed Change

- Technical Description:

- Attachments (Drawings, CAD Files, Photos, BOMs, etc.):

☐ Yes ☐ No (If yes, list file names or reference IDs: _____________________)

4. Additional Notes

Submit your engineering change management companion forms —

- Engineering Change Management Impact Analysis Form

- Engineering Change Management Approval Workflow Form

- Engineering Change Management Implementation Plan Form

- Engineering Change Management Change Review Board (CRB) Evaluation Form

- Engineering Change Management Execution & Monitoring Form

- Engineering Change Management Closure Review Form

Ensure that your Engineering Change Management forms have the same format. They should work together in a single change management packet.

Engineering change management request form for a service

Engineering change management request form for services

Here’s a streamlined Engineering Change Management (ECM) Request Form adapted specifically for services. You will fill out Impact Analysis, Approval Workflow, and Implementation Plan as separate forms later.

Engineering Change Management (ECM) Request Form – Service

Form ID: ___________________________

Date Submitted: ____________________

Requested By: ______________________

Department: ________________________

Contact Email/Phone: ________________

1. Change Request Summary

| Field | Description |

|---|---|

| Service Name | _________________________________________ |

| Service Code/Identifier | _________________________________________ |

| Current Version/Revision | _________________________________________ |

| Proposed New Revision/Version | _________________________________________ |

| Change Type | ☐ Process Update ☐ Scope Modification ☐ Compliance Requirement ☐ Documentation Update ☐ Other: ___________ |

| Urgency Level | ☐ Routine ☐ High Priority ☐ Immediate/Stop-Ship |

2. Reason for Change

- ☐ Service quality improvement

- ☐ Cost efficiency

- ☐ Customer feedback/request

- ☐ Regulatory/compliance requirement

- ☐ Correct service delivery issue

- ☐ Other: __________________________

Detailed Description of Issue or Opportunity:

3. Description of Proposed Change

Proposed Service Change Description:

Attachments (Process Maps, SOPs, Training Materials, etc.):

☐ Yes ☐ No (If yes, list file names or reference IDs: _____________________)

4. Additional Notes

Submit your companion engineering change management forms for service changes—

- Submit your engineering change management companion forms —

- Engineering Change Management Impact Analysis Form

- Engineering Change Management Approval Workflow Form

- Engineering Change Management Implementation Plan Form

- Engineering Change Management Change Review Board (CRB) Evaluation Form

- Engineering Change Management Execution & Monitoring Form

- Engineering Change Management Closure Review Form

Ensure that your Engineering Change Management service forms have the same format. They should work together in a single change management packet.

Beyond engineering change management, here are more personal development tools we found success with:

- See more on effective change processes in Planning Tools & Templates”

- See personal productivity tips (Self-Improvement Laws & Journal Tips).

2. Impact Assessment and Analysis

This is where many businesses fail. They rush to implement without understanding the ripple effects. I learned this lesson while building We Level Up. Every change, no matter how small, affects many parts of your business.

Create a comprehensive analysis covering:

- Technical implications

- Cost impact (materials, labor, time)

- Manufacturing/process changes required

- Quality and regulatory considerations

- Customer and market effects

- Supply chain implications

Engineering change management request Impact Assessment and Analysis for product and service form

Engineering Change Management (ECM) Impact Assessment & Analysis form

Here’s a detailed Engineering Change Management (ECM) Impact Assessment & Analysis form. It works for both products and services. The form has clear sections, so you can use it for either.

Engineering Change Management (ECM) – Impact Assessment & Analysis Form for Products and Services

Form ID: ___________________________

Linked ECM Request Form ID: ___________________________

Date: ______________________________

Prepared By: ________________________

Department: _________________________

1. Change Identification

| Field | Description |

|---|---|

| Type of Change | ☐ Product ☐ Service ☐ Both |

| Brief Change Summary | _________________________________________ |

| Reference Documents | _________________________________________ |

2. Business Impact

| Impact Area | Description | Effect | Estimated Value/Cost |

|---|---|---|---|

| Revenue Impact | How will this affect sales, pricing, or revenue? | ☐ Increase ☐ Decrease ☐ None | __________ |

| Customer Satisfaction | Will it improve or risk service/product experience? | ☐ Positive ☐ Negative ☐ Neutral | N/A |

| Market Competitiveness | Will it enhance competitive positioning? | ☐ Yes ☐ No | N/A |

3. Technical & Operational Impact

| Area | Description | Effect |

|---|---|---|

| Design/Specifications | Will design, technical specs, or features change? | ☐ Yes ☐ No |

| Production/Service Delivery Process | Will procedures, steps, or methods change? | ☐ Yes ☐ No |

| Equipment/Tools/Software | Will new tools or systems be required? | ☐ Yes ☐ No |

| Maintenance & Support | Will service/maintenance procedures change? | ☐ Yes ☐ No |

| Training Needs | Will staff require retraining? | ☐ Yes ☐ No |

4. Supply Chain & Resource Impact

| Area | Description | Effect |

|---|---|---|

| Material Requirements (Product only) | New materials or changes to suppliers? | ☐ Yes ☐ No |

| Vendor/Partner Changes | Will external service/product providers be impacted? | ☐ Yes ☐ No |

| Inventory Impact | Will existing stock be obsolete, reworked, or unaffected? | ☐ Scrap ☐ Rework ☐ Use-As-Is ☐ No Change |

| Staffing Impact | Will headcount or skill mix need adjustment? | ☐ Increase ☐ Decrease ☐ No Change |

5. Regulatory, Compliance & Risk

| Area | Description | Effect |

|---|---|---|

| Regulatory Approval | Will new certification or compliance steps be needed? | ☐ Yes ☐ No |

| Safety & Environmental Impact | Any changes to safety, environmental, or hazard controls? | ☐ Yes ☐ No |

| Legal Risks | Potential contractual, liability, or IP issues? | ☐ Yes ☐ No |

| Customer Contractual Impact | Will SLAs, warranties, or service agreements change? | ☐ Yes ☐ No |

6. Financial Impact Summary

| Cost Element | Estimated Cost (+/-) | Notes |

|---|---|---|

| Design/Engineering Updates | __________ | |

| Production/Service Delivery Changes | __________ | |

| Tooling/Equipment/Software | __________ | |

| Training | __________ | |

| Regulatory/Certification | __________ | |

| Other (specify) | __________ | |

| Total Estimated Impact | __________ |

7. Overall Risk Rating

| Risk Area | Low | Medium | High | Notes |

|---|---|---|---|---|

| Schedule Delay Risk | ☐ | ☐ | ☐ | |

| Cost Overrun Risk | ☐ | ☐ | ☐ | |

| Quality Risk | ☐ | ☐ | ☐ | |

| Customer Impact Risk | ☐ | ☐ | ☐ |

8. Additional Notes & Recommendations

This Engineering Change Management (ECM) Impact Assessment & Analysis form can be used right after you submit an ECM Request Form. You should use it before finishing the Approval Workflow form.

Submit your companion engineering change management forms for your change management plan:

- Submit your engineering change management companion forms —

- Engineering Change Management Impact Analysis Form

- Engineering Change Management Approval Workflow Form

- Engineering Change Management Implementation Plan Form

- Engineering Change Management Change Review Board (CRB) Evaluation Form

- Engineering Change Management Execution & Monitoring Form

- Engineering Change Management Closure Review Form

Ensure you create matching Engineering Change Management (ECM) Approval Workflow and Implementation Plan forms. This will help all three documents work together as one ECM packet. That way, product and service change requests will flow cleanly from request → analysis → approval → execution.

Lift yourself up beyond engineering change management. Here are more tools we found success with:

- See more on effective change processes in Personal Growth Books Quotes & Tips

3. Change Review Board (CRB) Evaluation

Establish a cross-functional Change Review Board with representatives from:

- Engineering/Product Development

- Operations/Manufacturing

- Quality Assurance

- Sales and Marketing

- Finance

- Customer Service

- Regulatory (if applicable)

The CRB evaluates each request against established criteria and makes go/no-go decisions. This collaborative approach ensures all perspectives are considered and builds organization-wide buy-in.

Engineering change management Workflow Approval form for products and services

Engineering Change Management (ECM) – Approval Workflow Form

Here is an Engineering Change Management (ECM) Approval Workflow form. It works with your Request Form and Impact Assessment & Analysis Form. It’s structured so it works for both products and services, with clear responsibility and tracking fields.

Engineering Change Management (ECM) – Final Execution Approval Form

Form ID: ___________________________

Linked ECM Request Form ID: ___________________________

Linked Impact Assessment Form ID: _____________________

Linked Review Workflow Form ID: _______________________

Date Prepared: _____________________

Prepared By: ________________________

Department: _________________________

1. Change Overview

| Field | Description |

|---|---|

| Change Type | ☐ Product ☐ Service ☐ Both |

| Change Title / Brief Description | _________________________________________ |

| Purpose of Change | _________________________________________ |

| Urgency Level | ☐ Routine ☐ High Priority ☐ Immediate |

| Reference Documents Verified | ☐ ECM Request Form ☐ Impact Assessment ☐ Review Workflow Form ☐ Supporting Attachments |

2. Execution Readiness Confirmation

| Readiness Area | Yes | No | Comments |

|---|---|---|---|

| All reviews completed and documented | ☐ | ☐ | |

| All conditions from review stage met | ☐ | ☐ | |

| Budget approved and allocated | ☐ | ☐ | |

| Resources assigned | ☐ | ☐ | |

| Timeline confirmed | ☐ | ☐ | |

| Regulatory/compliance sign-off obtained (if required) | ☐ | ☐ | |

| Communication plan ready | ☐ | ☐ |

3. Final Execution Approval

| Field | Description |

|---|---|

| Final Decision | ☐ Approved for Execution ☐ Not Approved ☐ Approved with Modifications |

| Conditions (if applicable) | _________________________________________ |

| Effective Start Date | _________________________________________ |

| Authorized Approver Name | _________________________________________ |

| Signature | _________________________________________ |

| Date | _________________________________________ |

4. Notes for Implementation Team

✅ Usage:

- This form is signed only once all review workflows are complete.

- It serves as the official green light for the implementation team.

- Should be stored with the ECM packet for compliance and audit trails.

Complete and submit your engineering change management Review Workflow Form. Next, go on to your final execution approval engineering change management form, so you have the full chain:

Request → Impact Assessment → Review Workflow → Final Execution Approval → Implementation.

4. Change Implementation Planning

Once approved, create a detailed Engineering Change Order (ECO) that includes:

- Step-by-step implementation plan

- Responsibility assignments

- Timeline with milestones

- Communication strategy

- Risk mitigation measures

- Success metrics

Engineering change management Change Implementation Planning form

Change Implementation Planning Form

Here’s the Change Implementation Planning Form redesigned as a proper fillable form with lines and spaces for users to write in responses.

Change Implementation Planning Form

1. Change Overview

- Change Request ID: __________________________________________________________________

- Title of Change: ______________________________________________________________________

- Date of Approval: ____________________________________________________________________

- Approved By: _________________________________________________________________________

- Implementation Start Date: _________________________________________________________

- Implementation End Date: ___________________________________________________________

2. Implementation Team

- Project Manager: _____________________________________________________________________

- Lead Engineer: ________________________________________________________________________

- Quality Assurance Lead: _____________________________________________________________

- Operations Lead: _____________________________________________________________________

- Other Key Personnel: ________________________________________________________________

3. Implementation Plan

- Step-by-Step Implementation Tasks:

- Resources Required: _______________________________________________________________

- Training Requirements: ____________________________________________________________

- Documentation Updates Needed: _________________________________________________

4. Risk Assessment

- Identified Risks: __________________________________________________________

- Mitigation Strategies: __________________________________________________________

- Contingency Plans: __________________________________________________________

5. Communication Plan

- Internal Communication: __________________________________________________________

- External Communication: _________________________________________________________

- Frequency of Updates: _____________________________________________________________

6. Post-Implementation Review

- Evaluation Criteria: _______________________________________________________________

- Feedback Mechanisms: ___________________________________________________________

- Review Date: _______________________________________________________________________

- Sign-Off (Project Manager / QA / Management): _______________________________

5. Execution and Monitoring

Implementation requires disciplined project management. I recommend these best practices:

- Phased Rollout: Implement changes in stages when possible to minimize risk

- Clear Communication: Keep all stakeholders informed throughout the process

- Documentation Updates: Ensure all technical documents, procedures, and training materials reflect the changes

- Progress Tracking: Monitor against your change management plan metrics

- Issue Resolution: Address problems immediately before they compound

Engineering change management Execution and Monitoring form for products and services

Engineering Change Management Execution & Monitoring Form

Here is your Engineering Change Management – Execution & Monitoring form. It works with the Request Form → Impact Assessment → Review Workflow → Final Execution Approval process you already use. It covers both products and services, with clear tracking for execution tasks, responsibilities, and monitoring checkpoints.

Engineering Change Management (ECM) – Execution & Monitoring Form

Form ID: ___________________________

Linked ECM Request Form ID: ___________________________

Linked Impact Assessment Form ID: _____________________

Linked Review Workflow Form ID: _______________________

Linked Final Execution Approval Form ID: _______________

Date Prepared: _____________________

Prepared By: ________________________

Department: _________________________

1. Change Overview

| Field | Description |

|---|---|

| Change Type | ☐ Product ☐ Service ☐ Both |

| Change Title | _________________________________________ |

| Purpose of Change | _________________________________________ |

| Approved Start Date | _________________________________________ |

| Target Completion Date | _________________________________________ |

| Responsible Project Lead | _________________________________________ |

2. Execution Task Plan

| Task Description | Owner | Start Date | Due Date | Status ☐ Not Started ☐ In Progress ☐ Completed | Notes |

|---|---|---|---|---|---|

3. Resource Allocation

| Resource Type | Description | Assigned To | Date Assigned | Notes |

|---|---|---|---|---|

| Personnel | ||||

| Tools/Equipment | ||||

| Software/Systems | ||||

| Materials (for product changes) |

4. Monitoring & Quality Checkpoints

| Monitoring Activity | Responsible Person | Date | Status ☐ Pass ☐ Fail | Corrective Action Required | Notes |

|---|---|---|---|---|---|

5. Risk Tracking During Execution

| Risk Description | Risk Level ☐ Low ☐ Medium ☐ High | Mitigation Action | Owner | Status |

|---|---|---|---|---|

6. Progress Summary

Weekly / Bi-Weekly Progress Updates:

Percent Completion: ______%

Schedule Variance: ☐ On Track ☐ Ahead ☐ Behind (by _____ days)

7. Handover to Closure

| Field | Description |

|---|---|

| All tasks completed? | ☐ Yes ☐ No |

| All quality checks passed? | ☐ Yes ☐ No |

| Training/communication delivered? | ☐ Yes ☐ No |

| Documentation updated? | ☐ Yes ☐ No |

| Ready for formal closure approval? | ☐ Yes ☐ No |

8. Execution Sign-Off

| Name | Role | Signature | Date |

|---|---|---|---|

| Project Lead | |||

| Quality/Service Lead | |||

| Department Manager |

✅ Usage Notes:

- This form lives during the change execution phase and is updated regularly.

- Monitoring sections allow tracking of real-time performance, risks, and quality results.

- Once execution is complete, this form feeds into the ECM Closure & Verification record.

Next, submit your final engineering change management (ECM) Closure & Verification Form so your system has:

Request → Impact Assessment → Review Workflow → Final Execution Approval → Execution & Monitoring → Closure

6. Post-Implementation Review

After implementation, conduct a thorough review to:

- Verify the change achieved its intended objectives

- Identify lessons learned for future improvements

- Update your change management process based on what worked and what didn’t

- Celebrate successes with your team

Engineering change management Post-Implementation Review form for products and services

Engineering Change Management (ECM) – Closure Review Form

Here’s a detailed Engineering Change Management – Post-Implementation Review form for both products and services. It is designed to assist you in completing your ECM process.

It follows your workflow:

Request → Impact Assessment → Review Workflow → Final Execution Approval → Execution & Monitoring → Post-Implementation Review

Engineering Change Management (ECM) – Post-Implementation Review Form

Form ID: ___________________________

Linked ECM Request Form ID: ___________________________

Linked Impact Assessment Form ID: _____________________

Linked Review Workflow Form ID: _______________________

Linked Final Execution Approval Form ID: _______________

Linked Execution & Monitoring Form ID: _______________

Date Prepared: _____________________

Prepared By: ________________________

Department: _________________________

1. Change Overview

| Field | Description |

|---|---|

| Change Type | ☐ Product ☐ Service ☐ Both |

| Change Title / Brief Description | _________________________________________ |

| Implementation Start Date | _________________________________________ |

| Implementation Completion Date | _________________________________________ |

| Project Lead / Responsible Person | _________________________________________ |

2. Objectives & Success Criteria

| Objective | Was it achieved? ☐ Yes ☐ No ☐ Partially | Notes / Evidence |

|---|---|---|

| Improve product/service quality | ||

| Reduce costs / increase efficiency | ||

| Meet regulatory / compliance requirements | ||

| Enhance customer satisfaction | ||

| Other (specify) |

3. Performance & Outcomes

| Metric / KPI | Target | Actual | Variance | Notes |

|---|---|---|---|---|

| Quality / Defect Rate | ||||

| Delivery / Service Timeliness | ||||

| Customer Feedback / Satisfaction Score | ||||

| Cost Impact | ||||

| Other Key Metrics |

4. Issues & Lessons Learned

| Root Cause | Resolution / Action Taken | Owner | Notes |

|---|---|---|---|

Key Lessons Learned:

5. Recommendations for Future Changes

| Recommendation | Priority | Responsible Department / Person | Notes |

|---|---|---|---|

| ☐ High ☐ Medium ☐ Low | |||

| ☐ High ☐ Medium ☐ Low | |||

| ☐ High ☐ Medium ☐ Low |

6. Post-Implementation Sign-Off

| Name | Role | Signature | Date |

|---|---|---|---|

| Project Lead | |||

| Quality / Service Lead | |||

| Department Manager | |||

| ECM Process Owner |

✅ Usage Notes:

- Conduct this review after the change has been fully executed and stabilized.

- Evaluate whether objectives were met, KPIs achieved, and lessons learned are captured.

- Feed insights into continuous improvement for future ECM requests.

- Store with the full ECM packet for audit, compliance, and knowledge management.

Compile all six engineering change management (ECM) forms. Combine them into a single packet. This packet works for products and services. This packet should include:

- Engineering Change Management (ECM) Request Form

- Engineering Change Management (ECM) Impact Assessment & Analysis Form

- Engineering Change Management (ECM) Review Workflow Form

- Engineering Change Management (ECM) Final Execution Approval Form

- Engineering Change Management (ECM) Execution & Monitoring Form

- Engineering Change Management (ECM) Post-Implementation Review Form

- Engineering Change Management (ECM) Optional ECM Closure Summary

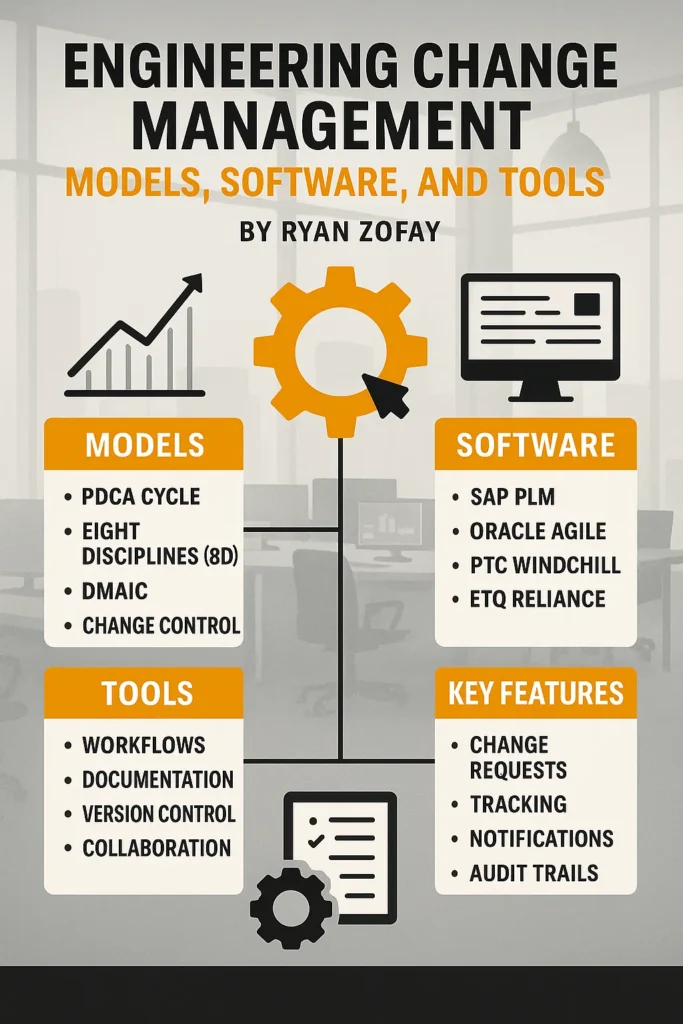

Engineering Change Management Models That Drive Results

Through my coaching work with entrepreneurs, I’ve identified three change management models that consistently deliver results:

The Lean Change Management Model

Perfect for fast-moving startups and small businesses:

- Streamlined approval process

- Rapid iteration cycles

- Continuous feedback integration

- Minimal documentation overhead

The Stage-Gate Model

Ideal for complex products or regulated industries:

- Formal review gates at each phase

- Comprehensive documentation requirements

- Risk assessment at every stage

- Clear go/no-go decision points

The Agile Change Management Model

Best for software and service businesses:

- Sprint-based change cycles

- Cross-functional collaboration

- Continuous improvement mindset

- Customer feedback integration

Essential Change Management Tools and Software

The right change management tools can make the difference between chaos and control. Here’s what I recommend based on real-world experience:

Document Management Systems

- Centralized Repository: Store all change-related documents in one accessible location

- Version Control: Track document revisions and ensure everyone has the latest information

- Access Controls: Limit editing permissions to authorized personnel

Workflow Automation Platforms

- Approval Routing: Automatically route changes to the right people for review

- Notification Systems: Keep stakeholders informed of status updates

- Deadline Tracking: Ensure changes move through the process on schedule

Change Management Software Features to Look For:

- Integration with existing systems (ERP, PLM, MES)

- Real-time collaboration capabilities

- Audit trail and compliance reporting

- Mobile accessibility for remote teams

- Customizable workflows to match your process

Popular options include:

- PTC Windchill (comprehensive PLM solution)

- Dynamics 365 Supply Chain Management

- Rootstock ERP (manufacturing-focused)

- Custom solutions built on Salesforce or Microsoft platforms

Real-World Success Stories

We Level Up Transformation

When I was building We Level Up, we reached a point where we had to completely update our service delivery model. Using the principles I’m sharing with you today, we:

- Established a formal change review process

- Created cross-functional teams for major initiatives

- Implemented staged rollouts for all service changes

- Developed feedback loops with both staff and clients

The result? We changed our operations and improved client satisfaction. Our team grew from 50 to over 600 professionals.

Manufacturing Client Case Study

One of my business coaching clients is a mid-size business. They were having trouble with engineering changes. These changes often led to production delays and quality problems. After implementing our engineering change management framework:

- Reduced change-related delays

- Decreased rework costs

- Improved customer satisfaction

- Shortened time-to-market for new initiatives

The key was establishing clear processes, empowering the right people to make decisions, and using technology to streamline communication.

Building Your Change Management Culture

Technology and processes are important, but culture is everything. Here’s how to build a change management culture that drives success:

Leadership Commitment

As the business owner, your commitment to proper change management sets the tone for your entire organization. When you consistently follow the process—even for urgent changes—your team will too.

Training and Development

Invest in change management consulting or training programs for your key team members. At We Level Up, we made change management training required for all department heads. This investment led to better execution.

Communication Excellence

Develop clear communication standards for change management:

- Who needs to be informed about different types of changes

- How changes are communicated (email, meetings, dashboards)

- Timeline expectations for responses and feedback

- Escalation procedures for urgent changes

Continuous Improvement

Your change management process should itself be subject to change. Regularly review and refine your approach based on:

- Feedback from team members

- Analysis of change outcomes

- Industry best practices

- Technology improvements

Common Engineering Change Management Pitfalls

Learn from my mistakes and those of the hundreds of entrepreneurs I’ve coached:

Rushing the Process

The Problem: Pressure to implement changes quickly leads to skipped steps and poor outcomes.

The Solution: Build time buffers into your process and educate stakeholders on why each step matters.

Inadequate Impact Assessment

The Problem: Focusing only on obvious impacts while missing hidden consequences.

The Solution: Use checklists and cross-functional teams to ensure comprehensive analysis.

Poor Communication

The Problem: Key stakeholders aren’t informed or don’t understand the implications of changes.

The Solution: Develop standardized communication templates and confirmation processes.

Lack of Documentation

The Problem: Changes are implemented without proper documentation, creating confusion later.

The Solution: Make documentation a non-negotiable requirement for change approval.

No Follow-Up

The Problem: Changes are implemented but never validated or optimized.

The Solution: Build post-implementation reviews into every change cycle.

Advanced Engineering Change Management Strategies

As your business grows, these advanced strategies become critical:

Predictive Change Management

Use data analytics to anticipate changes before they become urgent:

- Monitor customer feedback trends

- Track supplier performance indicators

- Analyze quality metrics for early warning signs

- Review market trends that might require product changes

Integrated Change Management

Connect your change management process with other business systems:

- Supply Chain Integration: Automatically notify suppliers of relevant changes

- Customer Communication: Keep customers informed of changes that affect them

- Financial Planning: Include change costs in budgeting and forecasting

- Regulatory Compliance: Ensure changes maintain compliance standards

Change Management Metrics

Track these key performance indicators to optimize your process:

- Average change cycle time

- Change implementation success rate

- Cost impact per change

- Customer satisfaction with changes

- Team productivity during changes

Frequently Asked Questions

How long should the change management process take?

The timeline depends on change complexity, but I recommend establishing standard timeframes:

- Simple changes: 1-2 weeks

- Moderate changes: 2-4 weeks

- Complex changes: 4-8 weeks

- Major changes: 8+ weeks

Remember, it’s better to take adequate time upfront than to deal with problems later.

What’s the difference between ECR and ECO?

An Engineering Change Request (ECR) is the first proposal for a change. An Engineering Change Order (ECO) is the approved plan to make that change. Think of ECR as “Can we make this change?” and ECO as “Here’s how we will make this change.”

How do I handle emergency changes?

Even emergency changes need process, but create an expedited path:

- Define what constitutes an emergency

- Establish emergency approval authority

- Document changes retroactively

- Conduct post-emergency reviews

What if team members resist the change management process?

Resistance usually comes from fear or misunderstanding. Address it through:

- Clear communication of benefits

- Training and support

- Involving resisters in process design

- Celebrating early wins

How do I measure ROI on change management investments?

Track quantifiable benefits:

- Reduced rework costs

- Faster time-to-market

- Improved quality metrics

- Higher customer satisfaction

- Better regulatory compliance

Optimizing your Engineering Change Management process is more than a procedural necessity—it’s a strategic advantage. By using best engineering change management practices, planning carefully, and monitoring progress, you can improve efficiency. Doing engineering change management well can reduce risk. It also ensures that every change has a genuine impact on the business.

Resources for Engineering Change Management Excellence

To support your change management journey, I’ve compiled resources from my ryanzofay.com platform:

Essential engineering change management complementary guides:

- Personal Development and Business Growth Strategies

- Leadership Excellence in Times of Change

- Building Resilient Business Systems

Training and Development

Community and Support

Planning Tools and Templates

Industry Insights and Trends

Implementation Support

- Change Management Consulting Services

- Process Optimization Strategies

- Technology Integration Planning

Your Next Steps to Engineering Change Management Excellence

Engineering change management isn’t just about managing modifications—it’s about building an organization that thrives on transformation. I built a successful business worth nine figures. I have also helped many entrepreneurs. I have seen how effective change management can make a difference. It separates successful businesses from those that struggle.

Remember, every challenge you face is an opportunity to grow stronger. Just like I changed from addiction and loss to business success, your business can overcome any challenge. With the right systems, mindset, and commitment to excellence, anything is possible.

The framework I’ve shared today has been battle-tested in real-world environments, from startups to established enterprises. But knowledge without action is worthless. The question isn’t whether you need better change management—it’s whether you’re ready to implement it.

Your competitors are already making changes to stay ahead. The market is evolving faster than ever. Your customers’ expectations continue to rise. The only question is: Will you be ready?

Start with one small improvement to your change management process this week. Document one change request that’s been floating around informally. Establish one new approval checkpoint. Create one communication template.

Small steps lead to significant transformations. Just as my journey from dark times to a successful business began with a single choice, your change can start with one decision. You must decide to embrace change with purpose and discipline.

The future belongs to engineering change management organizations that can adapt, evolve, and thrive through uncertainty. Make sure yours is one of them.

Ready to transform your approach to change management? Connect with me today and let’s build the systems that will drive your business to new heights.